The Manchester Tanker CIP

Why use HMD?

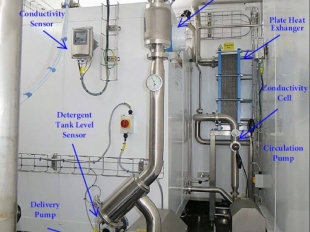

At our workshops in Northwich, HMD build bespoke automated CIP systems. Everything that we build complies with the latest BRC Food Safety Scheme and provides advanced cleaning control and ease of use.

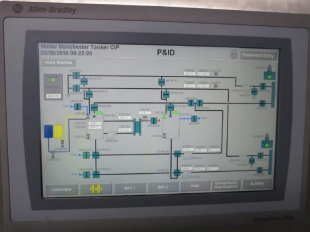

These systems are designed to remove waste residues and fats and disinfect the inside of bulk tankers after farm collections and the bulk transport of milk. Each tanker has its own data recording of flows, pressures and chemical strengths.

What are the advantages of this contained system for the customer?

Firstly, It is designed smaller to meet customer specification therefore takes up less room on site (not always applicaple to be designed this small).

Secondly, it is more efficient, as it can be completely built and tested within our workshop reducing time on site.

Thirdly, it is portable, meaning it can be easily transported, moved or re-sited should a new location be required.

Finally, automatic systems are more effective than manual cleaning, as they have controls in place to keep the clean consistent, repeatable with documentation to prove parameters are met such as conductivity control, temperature control, flow and level along with easy accessible sample points.